Choosing the right commercial 3D printing service is critical to the success of your project, whether you’re developing a prototype, custom part, or full-scale production run. With so many options available, selecting the best partner can be a challenge. Here’s a guide to help you make an informed decision when choosing the right 3D printing service for your needs.

1. Understand Your Project Requirements

Before searching for a commercial 3d printing services, it’s essential to define the scope and specific requirements of your project. Ask yourself the following questions:

- What is the purpose of the 3D printed part (e.g., prototype, functional component, end-use product)?

- What material properties are required (e.g., strength, flexibility, heat resistance)?

- What is the level of detail and precision needed for your design?

- How many units do you need (low-volume vs. high-volume production)? Understanding these factors will help narrow down service providers that specialize in the right materials, technologies, and production capabilities for your project.

2. Evaluate Technology and Capabilities

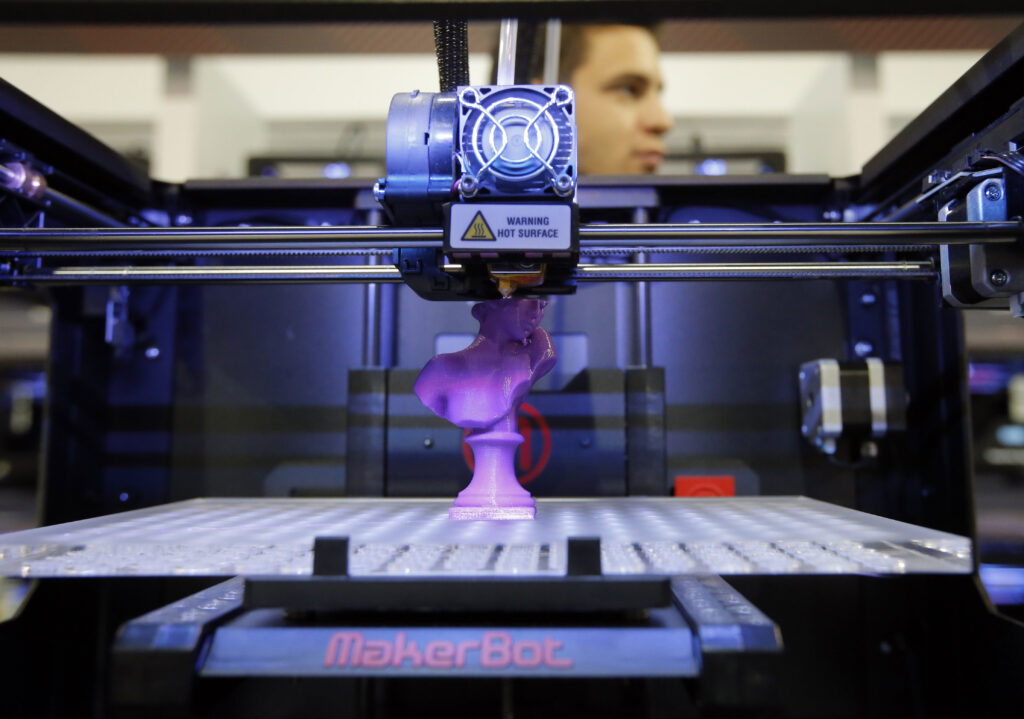

Different 3D printing technologies are suited for different applications. Common 3D printing methods include:

- Fused Deposition Modeling (FDM): Ideal for rapid prototyping and low-cost parts.

- Stereolithography (SLA): Offers high precision and smooth surface finishes, suitable for detailed prototypes.

- Selective Laser Sintering (SLS): Best for durable, functional parts with complex geometries.

- Metal 3D Printing: Suitable for producing strong, high-performance parts in industries like aerospace and automotive.

Ensure that the service provider you choose offers the right technology to meet your project’s specific needs. Some services may even offer a combination of technologies for more complex projects.

3. Check Material Options

The material used in your 3D printed part will impact its strength, durability, flexibility, and appearance. Commercial 3D printing services typically offer a range of materials, including:

- Plastics (e.g., ABS, PLA, nylon) for lightweight and cost-effective parts.

- Metals (e.g., stainless steel, titanium, aluminum) for high-strength and heat-resistant components.

- Resins for high-detail and smooth surface finishes, ideal for prototypes and models.

- Composites for applications requiring specific material properties, such as heat resistance or electrical conductivity.

Confirm that the 3D printing service offers the material options that meet your project’s requirements.

4. Review Production Speed and Lead Times

Time-to-market is a key factor for many businesses, especially in competitive industries. Before committing to a service, check their typical lead times and production speed. Some services specialize in rapid turnaround, while others may take longer for more complex or high-volume jobs.

Ask questions such as:

- How quickly can they deliver a prototype?

- What is the estimated production time for your entire order?

- Can they accommodate tight deadlines if necessary?

5. Assess Quality Control and Precision

Precision and consistency are crucial for projects that require tight tolerances or complex geometries. The quality of a 3D printed part can vary depending on the service provider’s expertise, equipment, and quality control processes. Ask potential providers about:

- Their quality control protocols.

- Certifications they may hold (such as ISO standards).

- Examples of previous work or case studies that demonstrate their ability to deliver high-quality parts.

6. Consider Scalability

If your project may require scaling up from prototyping to full-scale production, it’s important to choose a service provider that can handle both small and large orders. Discuss the scalability of their production capacity and whether they can maintain consistency across large production runs.

7. Compare Costs

While cost should not be the sole factor in your decision, it’s an important consideration. The cost of 3D printing services can vary significantly depending on factors like materials, technology, part complexity, and order volume. To ensure you get the best value:

- Request quotes from multiple service providers.

- Ask about pricing structures for different production volumes.

- Look for any hidden fees or additional costs (such as finishing or post-processing).

Be sure to balance cost with quality, speed, and reliability when making your decision.

8. Evaluate Customer Support and Expertise

The level of customer support can make a big difference in the success of your project. Look for a service provider that offers:

- Expert guidance: Providers with experience in your industry or similar projects can offer valuable advice on design optimization, material selection, and production processes.

- Clear communication: Reliable communication is essential for managing timelines, expectations, and any potential challenges during production.

- Post-production support: Whether it’s assembly, finishing, or troubleshooting, the best providers offer comprehensive support even after the parts are printed.

9. Check Reviews and References

Look for reviews or case studies from other clients to get a sense of the provider’s reputation. You can also ask the provider for references or examples of previous work that is similar to your project.

Key indicators of a reliable provider include:

- Positive feedback from past clients.

- A strong portfolio of completed projects.

- Transparent business practices and a track record of meeting deadlines.

10. Long-Term Partnership Potential

Finally, consider whether the service provider could become a long-term partner for your business. As your needs evolve, it’s beneficial to work with a provider that can grow with you, offering the necessary support for future projects or larger-scale production needs.

Conclusion

Selecting the right commercial 3D printing service for your project involves careful consideration of factors like technology, material options, production capabilities, and customer support. By doing thorough research and evaluating your specific needs, you can find a provider that not only meets your immediate project requirements but also offers long-term value for your business.